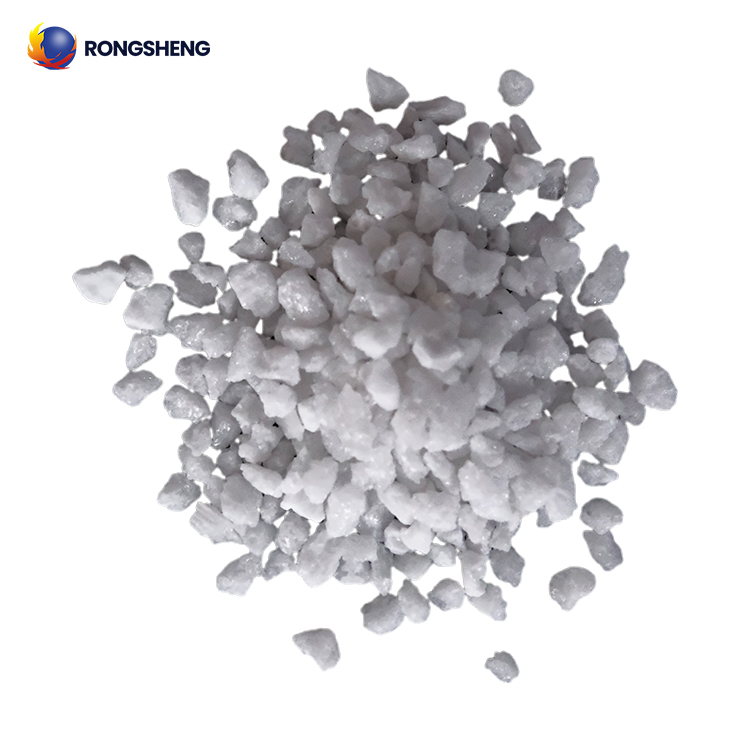

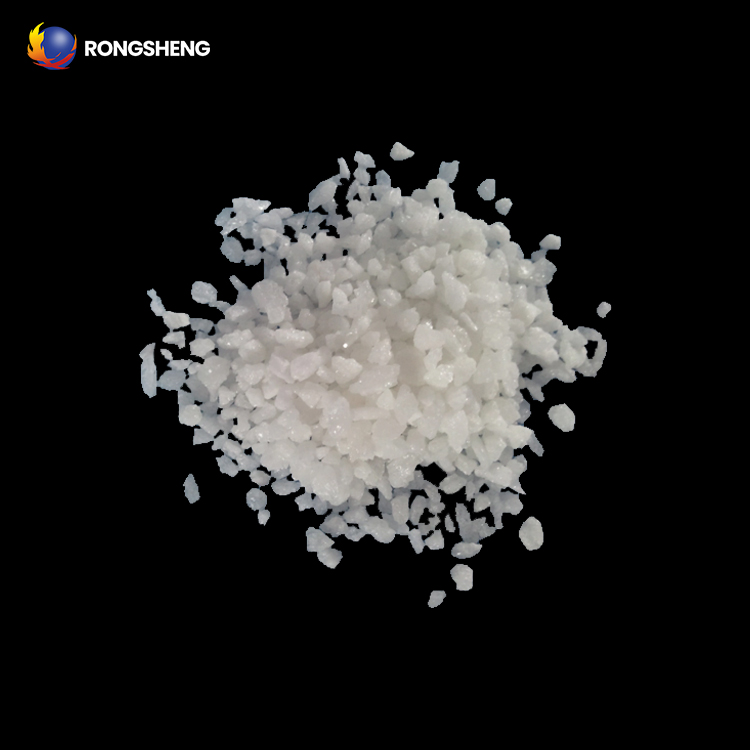

White Fused Alumina is a kind of artificial abrasive. It has a white color with a content of more than 99% aluminum oxide (Al2O3) and contains a small amount of iron oxide, silicon oxide and other ingredients. The particle size of White Fused Alumina(WFA) products is produced according to international standards and national standards, and can be processed according to the particle size required by users. The general particle size number is F4~F220, and its chemical composition varies depending on the particle size. The outstanding feature is that the crystal size is small and impact-resistant. If it is processed and crushed by an autogenous grinding machine, the particles are mostly spherical particles with a dry and clean surface, which is easy to bind with a binder.

Introduction of White Fused Alumina

White Fused Alumina is made from industrial alumina powder, which is melted in an arc at a temperature of more than 2000 degrees and then cooled. It is crushed and shaped, magnetically separated to remove iron, and sieved into various particle sizes. It has a dense texture, high hardness, and sharp-angled particles. It is suitable for making ceramics, resin-bonded abrasives, grinding, polishing, sandblasting, precision casting (special corundum for precision casting), etc. It can also be used to make advanced refractory materials.

Density of White Fused Alumina

There are two types of density of White Fused Alumina, one is bulk density and the other is true density.

- Bulk density, 1.53~1.99g/cm3. The bulk density of abrasive is related to factors such as the particle size of the abrasive, “composition of particle size”, variety and “particle shape”. Generally speaking, coarse-grained abrasives have a larger bulk density than fine-grained abrasives, and the bulk density of mixed-grained abrasives is greater than that of a single particle size.

- True density, 3.95~4.0g/cm3. The true density of abrasive refers to the mass of abrasive contained in a unit volume (excluding the volume of open pores).

- Basic particle size, 45%~55%. Basic particle size is an important indicator to ensure the grinding effect, and should be properly controlled during production, but the production speed may slow down.

Product Advantages of White Fused Alumina

- Does not affect the color of the workpiece.

- Can be used for sandblasting in processes where iron powder residue is strictly prohibited.

- Micro powder grade is very suitable for wet sandblasting and polishing operations.

- Fast processing speed and high quality.

- The amount of iron oxide contained is extremely low, suitable for sandblasting operations where iron residue is strictly prohibited.

- After pickling step to remove impurities.

RS White Fused Alumina

White Fused Alumina uses first grade low sodium industrial alumina as raw material, which is melted at 2250°C in a high-temperature electric arc furnace. It has the advantages of low sodium content, high purity, high temperature resistance, low porosity, large bulk density, good thermal stability, and good acid and alkali corrosion resistance.

RS White Fused Alumina Indicators

| Items | Unit | Grain | Fine Powder |

| Al2O3 | % | ≥99.50 | ≥99.30 |

| Na2O | % | ≤0.30 | ≤0.35 |

| SiO2 | % | ≤0.05 | ≤0.06 |

| Fe2O3 | % | ≤0.05 | ≤0.05 |

| Refractoriness | ℃ | ≥1850 | ≥1850 |

| Moh’s Hardness | / | ≥10 | ≥10 |

| True Density | g/cm3 | ≥3.9 | ≥3.9 |

| Bulk Density | g/cm3 | ≥3.6 | ≥3.6 |

White Fused Alumina Product Usage

White Fused Alumina is the main raw material for the production of amorphous and shaped refractory materials, and it is the main raw material for the production of amorphous refractory materials such as large ladle castable, medium and high grade iron hook castable, prefabricated parts, and various alumina products such as corundum bricks and high-temperature industrial kiln linings.

White Fused Alumina is suitable for the surface beautification of various high-end products, crafts or hardware products. After sandblasting, the surface is white and free of impurities, eliminating the trouble of cleaning. Fine White Fused Alumina(WFA) can be used as the first polishing and grinding. It can also be used as an additive for various products. It can be used as solid and coated abrasives, wet or dry or sprayed sand, suitable for ultra-fine grinding and polishing in crystal and electronics industries and making high-grade refractory materials. It is suitable for processing hardened steel, alloy steel, high-speed steel, high-carbon steel and other materials with hardness and high tensile strength. It can also be used as a catalyst, insulator and precision casting sand. It can remove rust, dirt and oxide scale from iron workpieces, and increase the adhesion of plating and coating. It can remove oxide scale from aluminum workpieces, strengthen the surface and have a polishing effect. It can remove oxide scale from copper workpieces, crystal frosting and engraving patterns on glass products, matte effect on plastic products, plush processing and effect patterns on special fabrics such as denim.

- Surface processing: removal of metal oxide layer, carbide black skin, metal or non-metal surface rust. Such as gravity die-casting mold, rubber mold oxide or release agent removal, ceramic surface black spots, uranium color removal, painting rebirth.

- Beautification processing: matte or matte treatment of various gold, K gold jewelry, precious metal products. Matte processing of non-metals such as crystal, glass, corrugated, acrylic, and can make the surface of the processed object metallic luster.

- Etching processing: etching art of jade, crystal, agate, semi-precious stone, seal, elegant stone, antique, marble tombstone, ceramic, wood, bamboo, etc.

- Pre-treatment processing: Teflon (TEFLON), PU, rubber, plastic coating, rubber roller (ROLLER), electroplating, metal spray welding, titanium plating, etc. before treatment to increase surface adhesion.

- Burr processing: burr removal of bakelite, plastic, zinc, aluminum die-casting, electronic parts, magnetic cores, etc.

- Stress relief processing: Stress relief processing for parts of aerospace, national defense, precision industry, rust removal, paint removal, matting, renovation, etc.

To purchase high-quality White Fused Alumina(WFA) products, please choose Rongsheng manufacturer. Cheap price and fast delivery. Contact Rongsheng for detailed information.