Mullite polyhydrogen insulation brick is also called light mullite brick or mullite thermal insulation brick. Zhengzhou Rongsheng refractory manufacturer will introduce you the characteristics and uses of mullite hydrogenated hydrogen brick JM-23 series.

Mullite Polyhydrogen Insulation Brick Description

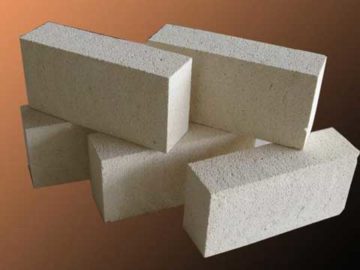

Mullite polymer brick is also called light mullite brick or mullite thermal insulation brick. It uses high-quality bauxite clinker as the main raw material. The foam method or chemical method forms a porous structure. It is made of high-quality heat-preservation and heat-preservation brick made of plastic mud or slurry and fired at high temperature after extrusion molding.

Mullite Polyhydrogen Insulation Brick Specifications

The standard size of mullite poly light brick is 230 * 114 * 65mm, the bulk density is generally 0.6-1.2g / cm3, and the operating temperature is 1300W-1550 degrees. Special-shaped sizes can be customized according to drawings. There are three types of JM-23, JM-26 and JM-28 according to the use temperature. This type of refractory product can directly contact the flame, and has the characteristics of high temperature resistance, mild high temperature, small thermal conductivity, and significant energy saving effects.

JM-23 Series Insulation Brick Index

|

JM-23 Series Insulation Brick Index |

|||||

| Items | JM – 23 – 0.6 | JM – 23 – 0.8 | JM – 23 – 1.0 | JM – 23 – 1.3 | JM – 23 – 1.5 |

| Al2O3 ≥ | 48 | 48 | 50 | 55 | 55 |

| Fe2O3 ≤ | 0.9 | 0.9 | 0.9 | 1.0 | 1.0 |

| Bulk Density (g/cm3) | 0.6 | 0.8 | 1.0 | 1.3 | 1.5 |

| Cold Crushing Strength (MPa) ≥ | 1.5 | 3.0 | 4.0 | 13.5 | 16 |

| Reheating line change is not more than 1% of experimental temperature (° Cx12h) | 1300 | 1300 | 1350 | 1350 | 1400 |

| Thermal conductivity (average temperature 350 ± 25 ° C) w / m.k | 0.20 | 0.23 | 0.33 | 0.35 | 0.40 |

| Thermal shock stability (1000 ° C air cooling / times) | 10 | 20 | 20 | 30 | 35 |

JM-23 Series Insulation Brick Features

(1) High temperature structural strength

(2) Low creep rate at high temperature

(3) Low thermal expansion coefficient

(4) Strong chemical resistance

(5) Good thermal shock resistance

(6) Can be used for lining of kiln working surface that directly contacts the flame

The performance of mullite insulation bricks is very high, and it can withstand high temperatures of up to 1800 degrees Celsius, but at 1600 to 1700 degrees Celsius, the insulation bricks will begin to soften and will not burn. Then its pressure resistance is also high, which is probably limited to 260M / pa.

Raw material composition of mullite insulation brick

As for how mullite insulation brick is made. It is based on high alumina bauxite clinker, plus a small amount of clay. Clay resources are well protected, so when the mullite insulation bricks appeared, the product of modern technology. Previously, aluminum was something that nobles could use, but modern technology makes aluminum a resource that can be used to produce various products.

Classification of mullite insulation brick

Mullite thermal insulation bricks are classified according to the density, and are divided into light mullite thermal insulation bricks and heavy mullite thermal insulation bricks. According to different operating temperatures, they are divided into 1350 mullite thermal insulation bricks and 1450 mullite thermal insulation bricks. Bricks, 1550 mullite bricks, etc., and above 1550 mullite bricks are generally used as bricks such as fire pits, because the heat-resistant temperature is high.

JM-23 Series Insulation Brick Usage

Mullite polymer light brick can be used as a hot surface refractory lining or other refractory materials as a backing insulation layer, used in the petroleum, chemical industry, ethylene cracking furnace, tube heating furnace, Taiwanese ammonia conversion furnace, gas generator, high temperature Industrial furnaces such as shuttle kiln, tunnel kiln, ceramic roller kiln, push plate kiln, refractory furnace, etc.

If your thermal equipment needs refractory bricks, mullite polyhydrogen insulation brick JM-23 series refractory brick products. Rongsheng refractory manufacturer will provide you with quality products and reliable service guarantee.