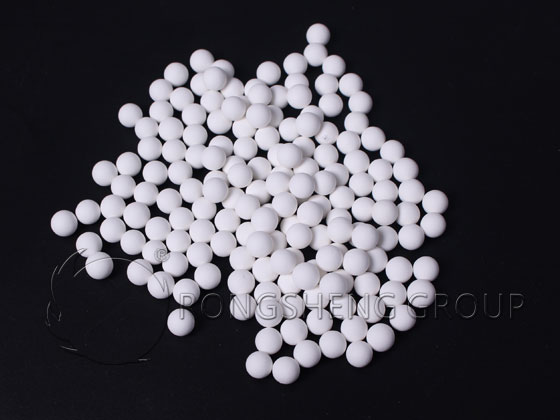

99.99 high purity alumina balls, also known as super wear-resistant alumina ceramic balls, are a kind of high purity alumina material. It has the characteristics of extremely high purity, excellent wear resistance, good corrosion resistance, high density and low water absorption. Its alumina content reaches 99.99%, and other contents are at PPM level, ensuring the excellent performance and stability of the material. 99.99 high purity alumina balls Manufacturer, 99.99 high purity alumina balls grinding media manufacturer.

Basic Characteristics of 99.99% High-Purity Alumina Balls

- High purity: 99.99 alumina balls have extremely high purity, ensuring the excellent performance and stability of the material.

- Wear resistance: Due to its uniform and fine α-alumina crystal structure, it has extremely high wear resistance, is not easy to break, and has a long service life.

- Corrosion resistance: It has strong corrosion resistance to acids and alkalis, and can maintain stable performance in harsh environments.

- High density and low water absorption: High density and low water absorption make it have better stability and durability in application.

High-Purity Alumina Balls Production Process

99.99 high purity alumina balls grinding media manufacturers’ 99.99 high purity alumina balls production process usually includes: raw material preparation, mixing, molding, drying, sintering and quality inspection. Parameters such as raw material purity, mixing uniformity, molding pressure, sintering temperature and time will affect the performance of the product.

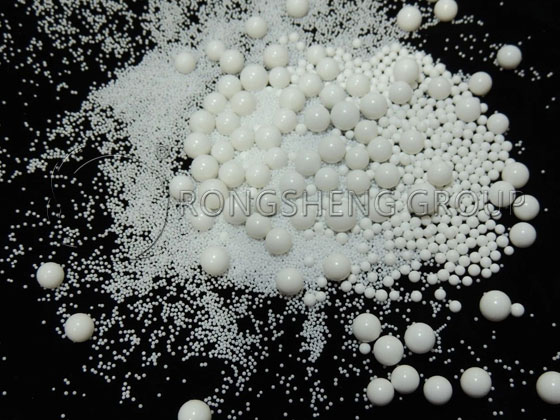

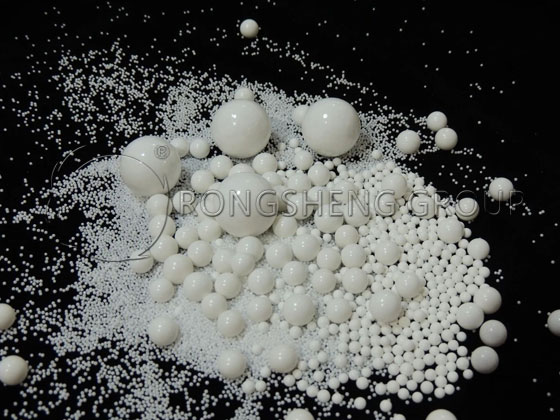

- Product specifications: 0.5-25mm, etc.

- Product content: 99.5%, 99.9%, 99.99%, etc.

99.99 High Purity Alumina Ball Grinding Media

High-purity nano-alumina balls (≥4N)

1) Alumina content: ≥99.99%.

2) Body density: 3.92-3.94 g/cm3.

3) Grinding ball size: 0.4-0.8mm/3.0-12.0mm.

4) Abrasion:

- 0.4-0.8mm 0.10g/kg·hr;

- 3.0-12.0mm 0.10g/kg·hr.

99 Nanometer Alumina Balls (≥99.0%)

1) Alumina content ≥99.0%.

2) Body density 3.86-3.90 g/cm3.

3) Grinding ball size: 0.4-0.8mm/3.0-12.0mm.

4) Abrasion:

- 0.4-0.8mm 0.16-0.20g/kg·hr;

- 3.0-12.0mm 0.15-0.18g/kg·hr.

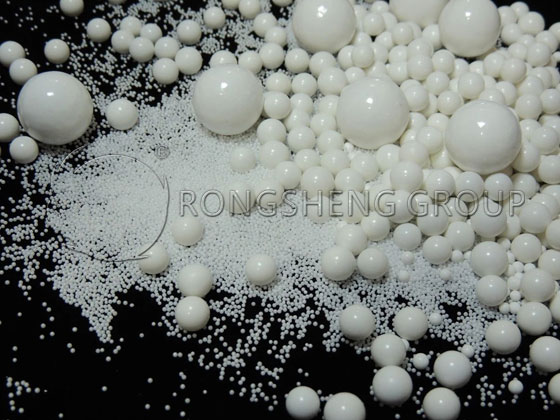

Modified zirconia microbeads

1) Zirconia content 60-80%.

2) Body density 5.20-5.60 g/cm3.

3) Grinding ball size: 0.4-0.8mm/3.0-12.0mm.

4) Abrasion:

- 0.4-0.8mm 0.04-0.06g/kg·hr;

- 3.0-12.0mm 0.06-0.08g/kg·hr.

Zirconia-toughened alumina microspheres

1) Zirconia content 20-40%, alumina content 60-80%.

2) Body density 4.35-4.75 g/cm3.

3) Grinding ball size: 0.4-0.8mm/3.0-12.0mm.

Application Fields of 99.99% High-Purity Alumina Balls

- Micro-grinding experiments and mass production: used for crushing and dispersing fine ceramic powders, crushing and dispersing electronic component materials, etc.

- Chemical and ceramic industries: used as grinding media, catalyst carriers, fillers, etc. to ensure product quality and stability.

- Electronics and semiconductor industries: used for implants, dielectric materials and insulating layers of electronic circuits, especially in the fields of electronic packaging and heat dissipation.

- Other fields: manufacturing industrial ceramic products such as alumina ceramics, ceramic abrasives, recycled balls, and as high-temperature furnace materials, refractory materials, etc.