Neutral refractories are primarily composed of mullite, corundum, or carbon (Al₂O₃, ZrO₂, CrO₃, SiC) as the main crystalline phase. At high temperatures, they exhibit good resistance to the chemical reactions of acidic slag, alkaline slag, fluxes, and other refractory materials, which can corrode other refractories. Strictly speaking, neutral refractories refer only to carbonaceous refractories, including carbon bricks and graphite-silicon carbide products. High-alumina refractories with a high Al₂O₃ content are also sometimes categorized under this term.

Application of Alumina Refractory Bricks in Glass Kilns

Alumina refractory bricks are commonly used in various kilns, including brick kilns and glass kilns. However, as a special refractory material, there are many precautions to take. So, what should be noted when using them in glass kilns?

- Because alumina refractory bricks cannot bear weight or pressure at high temperatures, they can only be used in the lower part of the kiln wall or in areas with lower temperatures at the bottom.

- The lining of important and complex-shaped parts should be pre-laid using alumina refractory brick-specific mortar for bonding.

- A small expansion joint should be left between alumina refractory bricks, with the gap controlled between 1.5mm and 2mm.

- During use, it is important to clean the dust and slag from the inner wall of the kiln shell to prevent loosening.

- The inside of the kiln shell must be flat, without unevenness or tilting.

- The joints must be secure. When processing bricks, a brick cutter must be used for fine processing; manual processing is prohibited. Joints and bends in flat surfaces must be at least half the size of the original brick. Original bricks must be used for jointing, and the processed surface of the brick must not face the inside of the furnace.

- Alumina refractory bricks must be stored in a dry warehouse.

Alumina refractory bricks are a type of heavy refractory material, covering SK32-SK38 refractory bricks, manufactured according to ASTM & JIS standards. The products are mainly used in the steel, non-ferrous metal smelting, chemical, building materials, glass, carbon, hot-fired, and coking industries. The operating temperature range is 1250°C – 1520°C.

Lightweight alumina insulating bricks are heat-insulating refractory products made primarily from fused alumina, sintered alumina, and industrial alumina. There are two production processes: the foaming method and the burnout additive method. In the foaming method, alumina insulating bricks are produced by grinding clinker, mixing it with a binder and foaming agent to form a slurry, casting it, and firing it at 1350-1500°C. The products have high refractoriness and good thermal shock resistance, and are commonly used as high-temperature insulation layers in kilns. The operating temperature is 1350-1500°C, and high-purity products can reach 1650-1800°C.

Applications of Neutral Refractory Materials

Alumina-carbon bricks, zirconium-carbon bricks, alumina bricks, silicon carbide bricks, and silicon nitride-bonded silicon carbide varieties, which have been developed in recent years, also belong to neutral refractories. Mullite, sillimanite, and corundum bricks are refractories that are slightly acidic to neutral. Corundum products containing more than 95% alumina are a widely used, high-quality refractories.

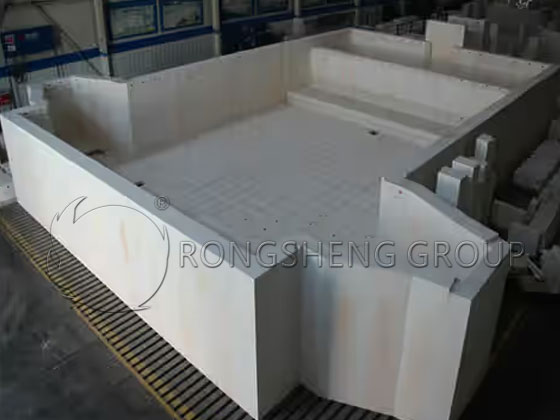

Neutral refractories can be used for blast furnace bottoms, belly or linings, aluminum electrode troughs, electrode furnaces, linings of high-temperature metal containers, and even in glass furnaces.

Chrome bricks are primarily composed of chromium oxide, made mainly from chromite, with chromite as the main crystalline phase. They have good resistance to steel slag corrosion, but poor seismic resistance and a low high-temperature load deformation temperature. Magnesia-chrome bricks made from chromite and magnesia in different proportions have good thermal shock resistance and are mainly used in open-hearth furnace roofs and in the regenerator compartments of glass furnaces, effectively storing calorific value.

Carbonaceous refractories are another type of neutral refractory material. Based on the composition and mineral structure of the carbon-containing raw materials, they are classified into three types: carbon bricks, graphite products, and silicon carbide products.

- Carbon bricks are made from high-quality petroleum coke as raw material, with tar and pitch as binders, and sintered at 1300℃ in an air-isolated environment.

- Graphite products (excluding natural graphite) are made from carbonaceous materials in an electric furnace at 2500℃-2800℃.

- Silicon carbide is made from silicon carbide minerals as raw material, with clay, silicon oxide, and other binders, and sintered at 1300℃-1450℃. Silicon carbide can also be mixed with silicon powder and sintered in a nitrogen atmosphere in an electric furnace to create silicon carbide-silicon carbide products.

Carbon products have a very low coefficient of thermal expansion at high temperatures, high thermal conductivity, and good heat resistance and shock resistance. It possesses high strength at high temperatures and will not soften even after prolonged use at high temperatures. It is resistant to corrosion from any acid, has good alkali resistance, and is not wetted by metals or slag, making it a high-quality high-temperature refractory material. Its disadvantage is that it is easily oxidized at high temperatures and is not suitable for use in oxidizing atmospheres. Carbon products are widely used in high-temperature furnace linings (furnace bottom, hearth, lower part of furnace body) and inner linings of furnaces for smelting non-ferrous metals. Graphite products can be used for reaction vessels and high-pressure reactor linings in petrochemical industries. Silicon carbide and graphite products can be used to make crucibles for smelting copper, gold, and light alloys.