In recent years, aluminum alloy products have become the most widely used non-ferrous metal materials. Therefore, melting furnaces and holding furnaces for aluminum alloy smelting is also increasing. During the smelting process of aluminum alloy, due to the long-term high-temperature erosion of molten aluminum, slag, and air, the refractory castables used are frequently damaged, which seriously affects the production needs of enterprises. Therefore, the search for refractory castables with high efficiency, corrosion resistance, and good performance has brought challenges and opportunities for refractory manufacturers. Rongsheng phosphate bonded refractory, high-alumina refractory manufacturers provide high-quality high-alumina refractory products for various thermal furnace equipment. Provide high-quality phosphate-bonded castable refractory and refractory brick products for aluminum melting furnace refractories. And customized refractory lining material products for various needs.

Characteristics of Phosphate Combined High Alumina Refractory Castables

The phosphate-bonded high-alumina refractory castable produced by Rongsheng refractory manufacturers has high density and high wear resistance. Compared with traditional high alumina refractory castables, it has the following main features.

- This high-alumina refractory castable is combined with phosphate liquid, and the material generates strength through a chemical condensation reaction, which has the advantages of fast hardening and high early strength. The strength of room temperature×3h is much higher than that of traditional high-alumina castables and low-cement castables.

- The castable binder is liquid phosphate, no need to add water during the construction process, to avoid performance deviation caused by the amount of water added. When packaging, the matrix material, and the binder are packaged separately, and the ratio is more accurate during the construction process.

- The phosphate-bonded castable refractory has strong corrosion resistance to molten iron and aluminum alloy solution.

- The castable can be well combined with other refractory materials, which can meet the needs of emergency and quick repair of kilns.

- Because there is no need to add water during the construction process, it can achieve rapid heating and rapid drying during the oven process. It avoids a series of problems like traditional cement-bonded refractory castables caused by improper ovens. This is more effective for irregularly shaped and thicker construction bodies.

Construction of Phosphate Combined High Alumina Refractory Castable

- Formwork. Formwork is a necessary link in the construction of phosphate-bonded castable refractory. When the phosphate-bonded high-alumina castable is used to set up the formwork, both metal formwork and wood formwork can be used. Metal formwork works well, but costs more. When using wooden formwork, pay attention to applying the lubricant evenly before installation and wiping off the excess. Prevent the combination of castable and furnace bodies from being affected by the lubricant falling on the surface of the hearth.

- Stir. Phosphate-bonded high-alumina castables harden quickly, so mixing times are short. It usually takes 2 minutes from stirring to pouring construction. More than 2 minutes may affect the construction quality. After the mixing operation is finished, the pouring material on the mixer should be cleaned up, and finally washed with water. Note that.

- 1) Once the material starts stirring, it cannot be stopped.

- 2) The material cannot see water during the stirring process. Otherwise, during the post-baking process, popping may occur.

- Pouring

- (1) Because the castable after stirring is very viscous and has poor fluidity, it will start to harden in a very short time. Therefore, pour it into the mold immediately after stirring evenly, and use a vibrator to smooth it immediately after pouring. If the construction volume is large, the vibrator should be used continuously, and if necessary, two vibrators should be used alternately. Note that the insertion depth of the vibrator should not exceed 60mm to prevent voids due to the rapid hardening of the material and affect the construction quality.

- (2) After hardening, the castable will bulge upward due to expansion and exceed the height of the designed construction body. Therefore, surface finishing should be carried out before the construction body is finally hardened.

- (3) After the construction is completed, the temperature of the construction body rises rapidly due to the chemical changes between the materials, and the strength increases sharply. If the temperature rises quickly, the mold can be hardened and removed in 30 to 60 minutes; if the temperature rises slowly, the mold can be removed in 3 hours. It should be noted that the longer the hardening time, the more difficult it is to remove the formwork. Therefore, the mold should be removed as soon as possible according to the temperature rise.

Rongsheng phosphate bonded castable refractory manufacturer, the use effect of phosphate bonded high alumina refractory castable provided. It not only effectively prolongs the service life of the aluminum melting furnace and the lining of the holding furnace, but also reduces the maintenance times. The practical application proves that after 5 months of use in the aluminum melting furnace, the slag hanging on the furnace wall is not obvious, and there is basically no trace of aluminum slag erosion.

The price of phosphate combined with high alumina refractory castables is much higher than that of traditional refractory castables. However, its strong anti-slag erosion, thermal shock stability, short construction time, and other advantages have achieved good application results in the application of aluminum melting furnaces and holding furnaces.

Two ways of phosphate binding monolithic refractories

There are two ways of phosphate combination, heating polycondensation combination, and room temperature accelerated hard combination.

In general, phosphate-bonded non-burning refractory materials are combined by heating and polycondensation. After heating, the phosphate binding phase undergoes very complex chemical changes. For example, after phosphoric acid and industrial alumina are mixed, they are heat-treated at 120°C to form phosphatite (AlPO4·2H2O). After heat treatment at 200°C, the binding phase is still phosphatite. After heat treatment at 350°C, phosphorite (AlPO4) is formed. After heat treatment above 500°C, the stable products AlPO4 of tridymite and cristobalite begin to form.

In another case, calcium aluminate cement or magnesium aluminum spinel is used as a hardening agent for phosphate-bonded monolithic refractories. First, condensation occurs by forming a double salt of high-valent metal ions such as aluminum calcium phosphate or aluminum-magnesium phosphate. Second, when the temperature rises, the residual phosphoric acid reacts with the refractory powder to form a stronger bond. Phosphoric acid not only has a corrosive effect on metallic iron, but also dissolves K+ and Na+ in the phosphate bonded castable refractory, and various impurities will enter the binder, affecting the high-temperature strength of the refractory.

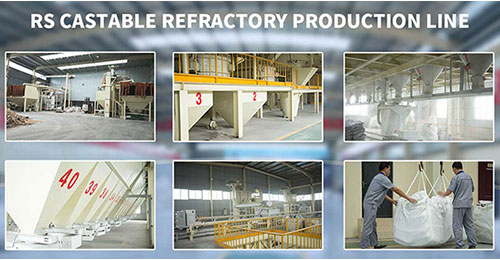

Rongsheng High Alumina Refractory Manufacturer

Rongsheng high-alumina refractory material manufacturers provide a variety of high-alumina refractory lining material products. Including various alumina refractory bricks, refractory castables, refractory plastics, refractory ramming materials, etc. We also conducted a comparative analysis of phosphate-bonded refractory bricks and castables products, aiming to provide customers with the most suitable refractory lining materials for their thermal furnaces according to their needs. We also have many cases of supplying refractories for aluminum melting furnace equipment. With a lot of experience in solving the problems of refractory lining of some aluminum melting furnaces we had accumulated, we can try to solve the problems you are facing now. To purchase phosphate-bonded high-alumina castables for aluminum melting furnaces, please contact us. Get prices and samples for free.