Generally, alumina refractory bricks are often used in various kilns, whether brick kilns or glass kilns. But as a special refractory material, there must be many precautions. So what should be paid attention to when using alumina refractory bricks in glass kilns?

- Because alumina refractory bricks cannot bear weight or pressure when used at high temperatures, they can only be used in the lower part of the pool wall or at the bottom of the pool where the temperature is lower.

- The lining of important and complex parts should be pre-built first, and special glue for alumina refractory bricks should be used for bonding.

- A little expansion joint should be left between alumina refractory bricks, and the gap between them should be controlled at 1.5mm-2mm.

- When using, pay attention to cleaning the dust and slag on the inner wall of the kiln shell, otherwise it will cause looseness.

- The inside of the kiln shell should be flat, without unevenness, and it should not be tilted.

- The lock seam should be firm. When processing bricks, the bricks should be finely processed with a brick cutter. Do not use manual processing bricks; the joint bricks and curved bricks on the plane should not be less than half of the original bricks. The original bricks must be used to lock the mouth, and the processed surface of the bricks cannot face the inside of the furnace.

- Alumina refractory bricks must be stored in a dry warehouse.

Alumina refractory bricks are a heavy refractory material. The product is mainly used in steel, non-ferrous metal smelting, chemicals, building materials, glass, carbon, hot spots, coking and other industries. Use temperature range: 1250℃ – 1520℃.

Refractory Materials for the Glass Industry

Refractory materials for the glass industry are developing in the direction of long life, high performance and low pollution. Using high and low glass phase permeation fused-cast bricks in the upper space of the glass kiln can effectively reduce the erosion of alkali vapor on refractory materials. Using corrosion-resistant fused-cast AZS in the glass tank kiln can improve the erosion of glass liquid along the brick joints. These are all conducive to extending the service life of the glass kiln, reducing the pollution of kiln refractory to glass liquid, and improving the quality of glass products. Using fused-cast spinel bricks, magnesia zirconium bricks, and even forsterite bricks in the regenerator can reduce the use of traditional magnesia-chrome checker bricks. On the one hand, it reduces pollution to the environment; on the other hand, it ensures the normal operation of the regenerator. It saves a lot of fuel purchase expenses for enterprises and reduces kiln maintenance costs at the same time.

Application of Fused Corundum Bricks in Glass Melting Furnaces

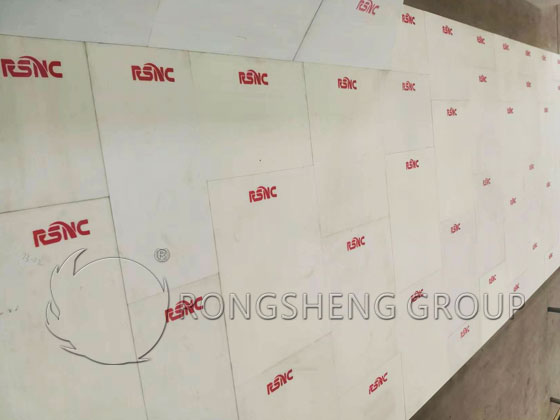

Fused corundum bricks are made by melting alumina in an electric arc furnace and casting it into a specified model of a specific shape. After annealing and heat preservation, the required product is obtained through processing. The general production process is to use high-purity calcined alumina (more than 95%) and a small amount of additives. After mixing, it is put into the electric arc furnace and cast into a prefabricated mold after high-temperature melting at more than 2300℃. Then it is taken out after heat preservation annealing. The taken out blank becomes a finished product that meets the requirements after precise cold processing, pre-assembly and inspection.

Based on the excellent performance of fused corundum bricks in terms of resistance to glass erosion, foaming, and stone resistance, especially its unique crystal structure, it has almost no pollution to the glass liquid. Therefore, it has important applications in the rear part of the melting zone, clarification zone, cooling section, flow channel, small furnace and other parts of the float glass melting furnace.

Fused corundum bricks are divided into three types according to the different forms and quantities of alumina crystals: the first type is mainly α-Al2 O 3, called α corundum bricks. The second type is mainly α-Al2 O 3 and β -Al 2 O 3 crystal phases, with roughly equal contents, called αβ corundum bricks. The third type is mainly β -Al 2 O 3 crystal phase, called β corundum bricks. The fused corundum bricks commonly used in float glass melting furnaces are the second and third types, namely fused αβ corundum bricks and β corundum bricks.

The mineral composition of fused αβ corundum bricks contains only a small amount of glass phase, which will not seep out and pollute the glass liquid when used, and has good corrosion resistance and excellent high temperature wear resistance below 1350 ℃. It is an ideal refractory material for the cooling pool wall, pool bottom and float glass melting furnace launder of the glass melting furnace. In float glass melting furnace projects, fused αβ corundum bricks are used as pool wall bricks in the cooling section of the glass melting furnace. In addition, paving bricks and cover bricks in the cooling section are also fused αβ corundum bricks.

Fused β-corundum bricks are white products composed of coarse β-Al2O3 crystals, containing 92%~95% Al2O3 and only less than 1% of glass phase. And due to the loose lattice, its structural strength is low, and the apparent porosity is less than 15%. Since Al2O3 itself is saturated with sodium above 2000℃, it is very stable to alkali vapor at high temperature, and its thermal stability is also excellent. However, when in contact with SiO2, the Na2O contained in β-Al2O3 decomposes and reacts with SiO2, and β-Al2O3 is easily transformed into α-Al2O3, resulting in a large volume shrinkage, causing cracks and damage. Therefore, it is only suitable for superstructures away from SiO2 fly ash. Such as the superstructure of the working pool of the glass melting furnace, the blast hole at the rear of the melting zone and the breast wall near it, the flat arch of the small furnace, etc.

Because it does not react with volatile alkali metal oxides, it will not cause molten material to seep out from the brick surface and contaminate the glass. In the float glass melting furnace, the alkaline vapor is easily condensed at this place due to the sudden narrowing of the flow channel entrance of the cooling section. Therefore, the flow channel flat arch here uses fused β bricks that are resistant to alkaline vapor corrosion.

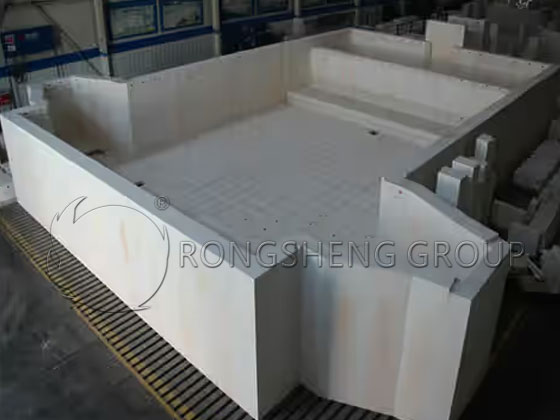

Large-Scale Fused-Cast α-β Alumina Flow Channel Bricks

The flow channel is the passage between the cooling part of the melting furnace and the tin bath, and is a key part of float glass production. Every day, hundreds of tons of glass liquid at about 1100℃ pass through the flow channel, which has a significant impact on the quality of the final float glass. Through the optimization design of material components and structures, large-scale fused-cast α-β alumina flow channel bricks are developed. In order to reduce the mortar joints, improve the air tightness of the glass melting furnace flow channel, and improve the uniformity of the liquid flow section temperature, the material selection requirements of the second-generation Chinese float glass system for energy saving, emission reduction and efficient operation are met.

- Develop new processes for high-temperature melting and heat preservation annealing to improve the casting quality, alkali vapor erosion resistance, wear resistance and erosion resistance of products.

- Develop new technologies for cold processing of curved surfaces to solve the technical problems of the special shapes of flow channel products, arcs, grooves and several inclined surfaces at different angles, which are difficult to grind precisely.

Large-scale fused-cast α-β alumina flow channel bricks are resistant to erosion and corrosion, which is conducive to eliminating defects such as lines, glass tendons and bubbles, and significantly improves the quality of float glass. The use of curved surface special-shaped processing technology has significantly improved the cold processing accuracy of α-β alumina flow channel bricks. The product structure is large-scale and the assembly quality is high, which meets the needs of high-quality and fast online overall hot replacement of flow channel bricks, and significantly shortens the production recovery time.

At present, it has been applied to hundreds of large float glass production lines at home and abroad with good results, and the comprehensive technical level has reached the international advanced level. To purchase high-quality alumina bricks, fused corundum bricks, fused αβ corundum bricks, and large-scale fused-cast α-β alumina flow channel bricks for glass kilns, please contact Rongsheng for free samples and quotations.