Light-Weight High Alumina Castables mainly use lightweight aggregates and heavy fine powder. Lightweight aggregates used in Light-Weight High Alumina Castable have larger pore diameters and lower strength. Therefore, the thermal conductivity of the lightweight castables is higher. At the same time, the low aggregate strength affects the overall strength of the lightweight castable, limiting its use at higher temperatures.

Features of High-Performance Light-Weight High Alumina Castable

In the working environment above 1200 ℃, high strength, low thermal conductivity, excellent construction performance. The high-performance light-weight high alumina castable fills the dilemma that the lightweight castable is difficult to be widely used in the medium and high-temperature area. In China, with the strengthening of resources, energy, and environmental protection constraints, green manufacturing, and environmentally friendly manufacturing will surely become the main directions of its transformation and upgrading. Therefore, the R&D and application of energy-saving technologies, energy-saving equipment, and energy-saving materials are of great significance.

The Application Introduction of Light-Weight High Alumina Castable

The performance of the lightweight high-alumina castable determines the energy-saving effect of thermal kilns. With the rapid development of various industries, the number and scope of light castable applications are gradually expanding. From the permanent layer, the heat insulation layer to the working layer, from the medium and low-temperature area to the medium and high-temperature area, the transition from a low load environment to a high load environment. At present, the performance of the lightweight high-alumina castable technology used in the working layer of the middle and low temperature (<1 200 ℃) and high temperature (>1 500 ℃) positions has basically matured. However, the performance of lightweight castables used in the medium and high-temperature range (1 200-1 500 ℃) needs to be improved to meet the new requirements for the use of lightweight high-alumina castables.

The performance of high-performance, Light-Weight High Alumina Castable fully considers various related factors affecting the castables. In the case of reducing production costs and meeting the conditions of use of castables, optimize the composition and configuration of castables, formulate reasonable production processes, and strengthen process control. The castable manufacturer has produced a series of high-performance lightweight high-alumina castables with bulk densities of 1.30 g/cm3, 1.50 g/cm3, and 1.80 g/cm3 to meet various working conditions.

Application Characteristics of High-Performance Light-Weight High Alumina Castables

High-performance Light-Weight High Alumina Castables can increase their strength and reduce thermal conductivity so that the castables have better construction performance and higher medium and high-temperature strength. Adopt the compound combination method of hydration combination and aggregation combination, which can improve the normal temperature and high-temperature performance of the castable. The developed high-performance light-weight high-alumina castable has lower thermal conductivity, higher high-temperature strength, and volume stability. It can be used in a variety of industrial furnaces at high temperatures between 1200 and 1500 ℃, with good results and obvious energy-saving effects.

What is the Difference between High Alumina Castable and High Alumina Steel Fiber Castable?

High-alumina castables and high-alumina steel fiber castables, both of which are actually high-alumina castables, are just the difference between adding or not adding steel fiber. We can find the difference between these two castables in terms of composition, performance, and use.

The first is the ingredients. Traditional refractory castables are unshaped refractory materials composed of refractory aggregate powder, binder, and a series of admixtures. Steel fiber refractory castable is added with 446# heat-resistant stainless steel fiber on the basis of traditional refractory castable. Some models such as 310#330#430# are also used, and the addition amount is 1%-3%. The following picture shows refractory castables and steel fiber castables.

Secondly, in terms of performance. Through the style of the refractory manufacturer and the actual use of thermal furnace equipment, it is proved that the traditional castable has improved the strain performance under stress after adding heat-resistant stainless steel fiber. Thereby improving the toughness, mechanical strength, and thermal shock resistance of the castable lining. However, the melting temperature and critical oxidation temperature of heat-resistant stainless steel fibers are relatively low, so they are not suitable for use at high temperatures. Otherwise, due to the melting and oxidation of the steel fiber, the structure of the refractory castable will be damaged or destroyed, resulting in the service life of the furnace or thermal equipment.

Finally, in terms of usage. Traditional refractory castables are mainly used for linings and burners of various heat treatment furnaces, high-temperature sections of lime shaft kilns, rotary kiln heads, preheating zones, etc. Steel fiber castables are mainly used in the lining of high-temperature cyclone separators of power plant boilers, combustion chamber furnaces, coal feeders; cement rotary kiln cooling drum linings, and other wear-resistant parts.

Rongsheng High Alumina Refractory Material Manufacturer

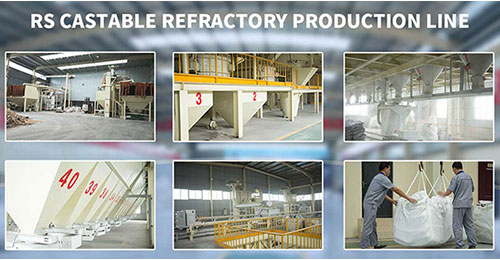

Rongsheng is an experienced manufacturer and seller of high-alumina refractories. Rongsheng’s high alumina brick products are hot-selling products. It also has strong strength in the production capacity of high-alumina castables. Rongsheng’s advanced and fully automatic environmentally-friendly unshaped refractory production line has an annual output of 80,000 tons. Purchase high-performance Light-Weight High Alumina Castable, high-alumina castables, and high-alumina refractory bricks from Rongsheng. To customize various refractory products for industrial furnaces, please contact us. We will get in touch with you shortly.