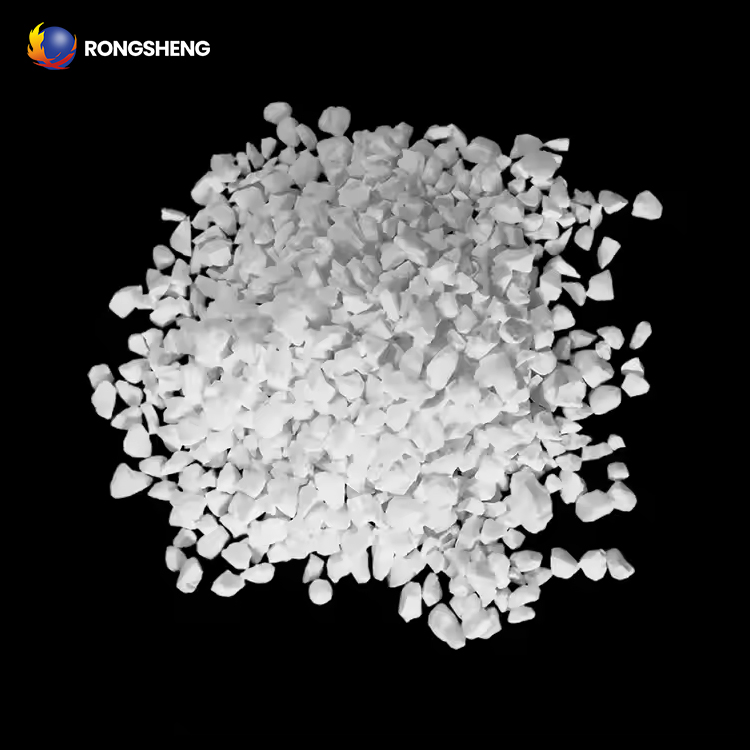

Tabular Alumina is a sintered corundum used in the steel and foundry industries. Tabular Alumina is a pure sintered corundum that shrinks completely after firing without any additives such as MgO and B2O3. Tabular Alumina has a coarse crystal structure with a well-developed α- Al2O3, and the content of Al2O3 is above 99%. It has a plate-like crystal structure, small pores and more closed pores, and the porosity is roughly the same as that of fused corundum. It has high purity, good volume stability, and very small re-firing shrinkage. The refractory or castable used in production has good thermal shock stability and bending strength after high-temperature treatment, but the price is higher than other aluminas.

Properties of Tabular Alumina

- High refractoriness.

- High corrosion resistance.

- High erosion resistance.

- High thermal shock stability.

- High strength and good toughness.

- Stable chemical properties.

RS Tabular Alumina

RS Tabular Alumina uses industrial alumina as the raw material, and is sintered in high-temperature vertical kiln with a temperature greater than 1900°C. The product is made of granular corundum crystals closely arranged, evenly distributed to each other, to achieve the best density and inter-granular strength. With high purity, low alkali, high strength, high thermal shock resistance, corrosion resistance properties, it mainly used as alumina base and alumina containing refractory bone material and substrate.

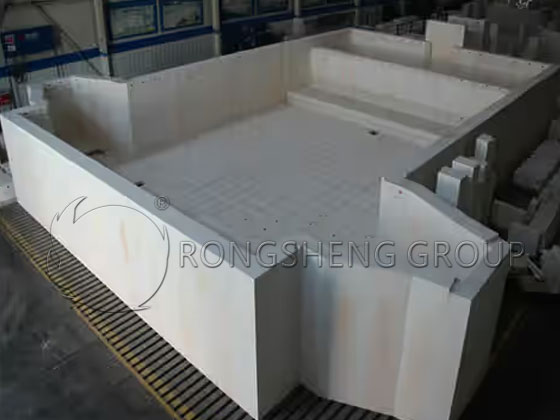

It is widely used in metallurgical refractory materials (slide, nozzle, porous plug brick, etc.), ceramic, chemical, glass, abrasives and other industries with refractory materials figured.

RS Tabular Alumina Indicators

| Items | Unit | Grain | Fine Powder |

| Al2O3 | % | ≥99.40 | ≥99.40 |

| Na2O | % | ≤0.40 | ≤0.40 |

| SiO2 | % | ≤0.09 | ≤0.09 |

| Fe2O3 | % | ≤0.07 | ≤0.09 |

| Magnetic Iron | % | ≤0.02 | ≤0.03 |

| Bulk Density | g/cm3 | ≥3.5 | ≥3.5 |

| Apparent Porosity | % | ≤5.0 | ≤5.0 |

| Water Absorption | % | ≤1.5 | ≤1.5 |

Application of Tabular Alumina

Tabular Alumina can be used as the main component in aluminum-carbon, aluminum-magnesium-carbon, magnesium-aluminum-carbon, magnesium-spinel, and aluminum-chromium refractory bricks. It can also be introduced as an enriched alumina component into high-aluminum amorphous refractory materials. It can be widely used in steel, casting, ceramics and other industries. Among them, the application in the steel industry almost covers the entire process of ironmaking and steelmaking. The application status of refractory materials made of Tabular Alumina in the steel industry is listed in the table below.

Application Status of Tabular Alumina Refractory Materials in Steel Industry

| Equipment | Application Parts | Types of Materials | Performance |

| Blast furnace | Lining, hot blast furnace, pouring field (main ditch, iron outlet ditch) | Aluminum-chrome bricks, high-aluminum bricks, high-aluminum castables, high-aluminum plastics, aluminum silicon carbide carbon castables | Good thermal shock resistance, resistance to alkaline slag erosion, high high-temperature strength |

| Mixed iron car | Working lining (slag wire brick, iron wire brick, top turn), aluminum carbon fire mud | Aluminum carbide silicon carbon brick, aluminum magnesium carbon brick, aluminum carbon brick, aluminum carbide silicon carbon refractory mud | Good resistance to slag erosion, good resistance to molten iron erosion |

| Ladle | Working lining, air-permeable bricks, nozzle seat bricks | Aluminum silicon carbide carbon bricks, aluminum-magnesium prefabricated parts, aluminum spinel prefabricated parts, magnesium-aluminum unfired bricks, aluminum-magnesium unfired bricks, aluminum spinel fired products | Good thermal shock resistance, good slag resistance, resistance to molten steel erosion, good air permeability |

| Tundish | Backup working lining, ladle cover | Low cement castable, high alumina precast bricks | Stable volume |

| RH | Dip tube, circulation tube | Corundum spinel castable, prefabricated parts | Good thermal shock resistance, good slag resistance |

| Nozzle | Long nozzle, immersed nozzle | Aluminum carbon water nozzle, aluminum carbon slide plate, etc. | Good thermal shock resistance, resistance to molten steel erosion |

| Sliding nozzle | Nozzle, slide plate | Aluminum carbon nozzle, corundum spinel pouring nozzle, aluminum carbon slide plate, etc. | Good thermal shock resistance, good corrosion resistance, |

| Heating furnace | Working lining | High-aluminum plastic, castable, prefabricated block | Stable volume, good insulation effect |