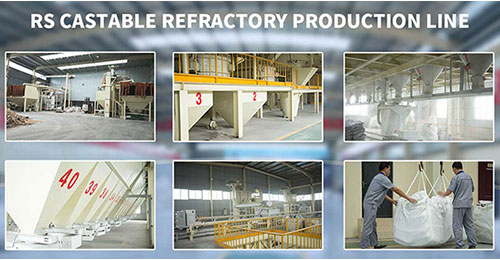

Aluminate cement is a kind of special cement, that also has many names. For example, refractory cement, 625 cement, high alumina cement, CA-50 cement, etc. Calcium Aluminate Cement Uses as a binder for monolithic refractory castables, aluminate cement has a wide range of applications and is mostly used for building and bonding kilns in the metallurgy, petrochemical, and cement industries. Rongsheng high-alumina refractory manufacturer has rich experience in the production and sales of high-alumina refractory bricks and high-alumina monolithic refractory castables. Moreover, the refractory products can be customized according to the different needs of the parts where the refractory materials are used.

What is Calcium Aluminate Cement?

In China, calcium aluminate cement is customarily divided into two categories, ordinary calcium aluminate cement (Al2O3 53~72%, CaO 21%~35%) and pure calcium aluminate cement (Al2O3 72%~82%, CaO 19%~23%). Ordinary calcium aluminate cement can be divided into low iron type (Fe2O3<2.0%) and high iron type (Fe2O3 7%~16%). Low-iron calcium aluminate cement with an Al2O3 content of 53% to 56% and a CaO content of 33% to 35% is called high alumina cement. Abbreviation HAC, also known as alumina cement. Al2O3 content of 59% to 61% and CaO content of 27% to 31% is called aluminum-60 cement. Low-calcium aluminate cement (high alumina cement-65) with Al2O3 content of 65%-70% and CaO content of 21%-24%. Pure calcium aluminate cement can be divided into ordinary type (Al2O3 72%~78%) and ultra-high aluminum type (Al2O3>79%~83%). In addition, according to the special requirements for certain physical properties, there are early-strength calcium aluminate cement and high-strength calcium aluminate cement, and other varieties.

Calcium Aluminate Cement Uses

Calcium aluminate cement is mainly used as a binder for refractory castables and refractory spraying materials. There are two main requirements for ordinary calcium aluminate cement.

(1) Appropriate coagulation time to ensure sufficient working time. It is generally required that the initial setting is greater than 1h and the final setting is less than 8h. The shorter the time interval between the initial setting and the final setting, the better;

(2) Sufficient early strength. That is, one day of curing can reach 60%~70% of the strength specified by the cement label. After 3 days of maintenance, it can reach more than 90%.

In addition to the above two points, pure calcium aluminate cement is also required to have a certain degree of refractoriness and good workability to meet the requirements of construction and high-temperature use.

Medium and low-grade refractory castables, such as clay and high-alumina castables, use ordinary calcium aluminate cement as the binder. High-grade refractory castables, such as corundum, mullite, chromium-containing corundum, corundum-spinel, and other castables use pure calcium aluminate cement as the binder. The addition of calcium aluminate cement in ordinary refractory castables is 10%~20%, the addition of low cement refractory castables is 5%~7%, and the addition of ultra-low cement castables is less than 3%.

Among unshaped refractory materials, castables with calcium aluminate cement as binders are widely used.

(1) The use temperature of clay castables is 1300-1450 degrees. It is generally used as the lining of steel rolling heating furnaces, various heat treatment furnaces, boilers, shaft kilns, and rotary kiln preheating belts.

(2) The service temperature of high alumina castable is 1400-1550 degrees. Can be used in various heat treatment furnace linings and burners. Tapping trough of electric furnace, a high-temperature section of lime shaft kiln, kiln head of rotary kiln, the inner lining of power plant boiler.

(3) The service temperature of corundum castable is 1500-1650 degrees. It is mainly used for the lining of various high-temperature furnaces and high-temperature components to buy the dipping tube of the molten steel vacuum degassing device, the lining of the jet metallurgy, and the argon-blowing integral spray gun. The triangular area lining of the electric furnace roof, the LF furnace cover, the high-temperature wear-resistant lining of the catalytic cracking reactor in the petrochemical industry, etc.

What are the composition and use of ordinary calcium aluminate cement castables?

Ordinary calcium aluminate cement is used as a binder, and the mixture is prepared in a certain proportion with refractory aggregate and powder. It can be used directly after adding water, stirring, vibrating casting, curing, and baking. Ordinary calcium aluminate cement can be divided into the low-iron type and high-iron type. The low-iron type produced in our country is sintered with natural low-silicon bauxite and limestone.

Ordinary calcium aluminate cement-bonded castables have a wide range of applications. Different types of calcium aluminate cement can be selected as binders according to the temperature and conditions of use, and different refractory aggregates and powders can be added. Usually used in various heat treatment furnaces in metallurgy, petrochemical, machinery, building materials, and other industrial sectors. Heating furnaces, soaking furnaces, tapping and tapping troughs, boilers, rotary kiln heads, and kiln tails. Linings for petrochemical reactors, various hot pipes, valves, etc.

Where to Buy Calcium Aluminate Cement?

No matter what method we use to understand where to buy calcium aluminum cement, the answer is basically the same. Try to choose reliable calcium aluminate cement manufacturers to purchase. If you really can’t find a suitable manufacturer, you can also purchase through calcium aluminum cement suppliers. No matter which procurement source you choose, calcium aluminum cement price is always the most competitive. Many calcium aluminate cement suppliers can provide various qualities of refractory cement. Before making a purchase, make sure to verify that the product you’re buying is the right type and grade of calcium aluminate cement for your specific project needs. This is not only a matter of cost savings but also of construction progress. Rongsheng high alumina refractory brick manufacturers can provide high-quality calcium aluminate cement products for the construction needs of various high-temperature kilns. Contact us to get a free sample.