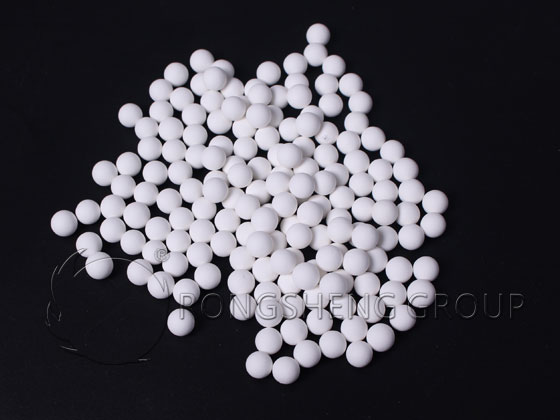

Inert alumina balls are referred to as inert porcelain balls. It is processed from high-quality chemical porcelain clay raw materials. It has the characteristics of high strength, high chemical stability, and thermal stability. So what are the differences between inert porcelain balls and activated alumina balls?

The Difference between Inert Porcelain Balls and Activated Alumina Balls

Inert porcelain balls can withstand high temperature, high pressure and corrosion from acids, alkali, salts and various organic solvents. Widely used in petroleum, chemical, fertilizer, natural gas and environmental protection industries. Inert alumina serves as the support and covering material for the reactor catalyst, which can buffer the impact of liquid and gas entering the reactor on the catalyst. Protect the catalyst and improve the distribution of liquids and gases in the reactor. Its main function is to increase gas or liquid distribution points, support and protect active catalysts with low strength.

Activated alumina balls have the characteristics of high strength, low wear, no softening by water intrusion, no expansion, no powdering, and no cracking. It has many capillary channels and a large surface area, and can be used as an adsorbent, desiccant and catalyst. It can be widely used for deep drying and hydrogen production of petroleum cracked gas and ethylene propylene gas, drying of air devices and instrument air dryers, and fluoride treatment in hydrogen peroxide. It can also remove sulfur hydrogen, sulfur dioxide, hydrogen fluoride, hydrocarbons and other pollutants in the exhaust gas. Especially suitable for defluoridation treatment of fluorinated water.

Activated alumina balls have good adsorption and defluorination effects and are easy to stabilize. Each cubic meter of activated alumina absorbs 6,400 grams of fluorine. At the same time, activated alumina balls have strong affinity for water, oxides, acetic acid, alkali, etc. It is a micro-water deep desiccant and an adsorbent for polar molecules.

Simply put, inert alumina balls are inert and will not react with materials and play a protective role. Activated alumina balls are active and will react with materials.

Application of Activated Alumina Balls and Inert Alumina Ceramic Balls

Since there is a difference between activated alumina balls and inert alumina ceramic balls, what devices are they used in? What’s the use?

- Activated alumina balls have a certain adsorption effect and can be used to adsorb some polar substances. Simply put, activated alumina is active and will react with materials. Activated alumina balls have many capillary channels and large surface area, and can be used as adsorbents, desiccants, and catalysts. At the same time, it is also determined according to the polarity of the adsorbed material, and has a strong affinity for water, oxides, acetic acid, alkali, etc. Activated alumina balls are a micro-water deep desiccant and an adsorbent for polar molecules. Activated alumina balls remove fluoride similar to anion exchange resin, but anion resin has greater selectivity for fluoride ions. Activated alumina has good adsorption and defluorination effect and stable capacity. Activated alumina absorbs 6400 grams of fluorine per cubic meter. The product has high strength, low wear, and does not soften when soaked in water, does not expand, does not pulverize, and does not crack. Application fields of activated alumina balls. Activated alumina balls can be widely used for deep drying of petroleum cracked gas, ethylene propylene gas and drying of hydrogen production, air separation units and instrument air dryers. Fluoride treatment in hydrogen peroxide can also remove sulfur hydrogen, sulfur dioxide, hydrogen fluoride, hydrocarbons and other pollutants in waste gas, and is especially suitable for defluoridation treatment of fluorinated water.

- Inert alumina ceramic balls are ordinary ceramic balls, which are used as separators before and after filling the catalyst layer during the reaction. Inert alumina balls are inert and will not react with materials and play a protective role. Inert ceramic balls have the characteristics of high strength, high chemical stability, and thermal stability. Inert porcelain balls can withstand high temperature, high pressure, and corrosion from acids, alkali, salts, and various organic solvents. Inert porcelain balls are mainly used in petroleum, chemical, fertilizer, natural gas, and environmental protection industries. Inert porcelain balls serve as support and covering materials for the catalyst in the reactor, which can buffer the impact of liquid and gas entering the reactor on the catalyst. Protect the catalyst and improve the distribution of liquids and gases in the reactor.

It is worth noting that activated alumina balls are generally not called porcelain balls, but inert alumina balls are called porcelain balls.