G-grade refractory bricks are products used in blast furnaces, and are generally made of high-alumina and clay materials, with custom-made products available in various materials. Examples include clay, high-alumina, silica, corundum, and mullite, meeting the requirements for blast furnace refractory bricks. G1-G8 are blast furnace refractory bricks, with high-alumina bricks and clay bricks being commonly used. Below is the standard specification for G-series tiles:

- G1: 230*15*75(mm)

- G2: 345*150*75(mm)

- G3: 230*150*135*75(mm)

- G4: 345*150*130*75(mm)

- G5: 230*150*120*75(mm)

- G6: 345*150*110*75(mm)

- G7: 230*150*90*75(mm)

- G8: 345*150*90*75(mm)

Blast Furnace Refractory Materials

There are many types of blast furnace refractory materials. Generally, high-performance clay bricks or high-alumina bricks are used in the upper and middle parts of the furnace body. Special refractories such as carbon-based bricks, silicon carbide bricks, mullite bricks, and corundum bricks are used in the lower part, waist, and belly of the furnace body. In particular, recently produced silicon carbide bricks have been successfully applied to blast furnaces. Other monolithic refractories are also widely used.

When constructing wall blast furnaces, hot blast stoves, or lime kilns, the combination of two brick types can create rings of different diameters to accommodate variations in furnace size and diameter as the furnace height changes. Typically, G1 insulating bricks are combined with G3 or G5 wedge bricks, and G2 insulating bricks are combined with G4 or G6 wedge bricks. Because the ring diameter varies during the wall-building process, the number of straight bricks and wedge bricks used also varies.

For the furnace lining walls, all circumferential joints must be staggered, and bricks must not be cut. If brick cutting is necessary, it needs to be ground smooth. The masonry thickness and staggered joints are composed of bricks with lengths of 230mm and 345mm. The masonry thickness can be adjusted by 115mm to achieve staggered joints. If the thickness variation is less than 115mm, it can be adjusted using filler joints between the masonry and the furnace shell or between the masonry and the cold wall.

The working conditions and damage mechanisms of various parts inside the furnace. The cooling equipment methods and their impact on the brick lining. It is necessary to predict whether the post-corrosion furnace internal shape is reasonable.

A reasonable brick type design is essential to ensure masonry quality. The thickness of insulating bricks is generally 75mm, which allows for small horizontal joints. Insulating bricks are available in lengths of 230mm and 345mm for easy staggered joints. There are two types of bricks: straight insulating bricks and wedge-shaped insulating bricks. Wedge-shaped insulating bricks or straight insulating bricks used alone or in combination with wedge-shaped insulating bricks are used to construct walls, producing annular furnace charge of any diameter to meet the needs of blast furnaces with different capacities.

The number of bricks can be calculated by dividing the total volume of the bricks in the furnace bottom by the volume of each brick. When calculating the number of bricks in each layer, the horizontal cross-sectional area of the bottom bricks can be divided by the corresponding surface area of each brick. A loss of 2% to 5% is generally considered.

If the weight of the bricks needs to be calculated, multiply the weight of each brick by the number of bricks. Other parts of the blast furnace are cylindrical or conical. A ring should be constructed for both the base layer and the inner surface layer. When constructing a ring, wedge-shaped insulating bricks are necessary. If constructing any straight body, a ring must be built for both the base layer and the inner surface layer. Wedge-shaped insulating bricks must be used when constructing the ring.

If constructing a ring of any diameter, wedge-shaped insulating bricks and straight insulating bricks must be used in combination. Generally, G11 straight insulating bricks are used in combination with G13 or G15 wedge-shaped insulating bricks, and G2 straight insulating bricks are used in combination with G4 or G16 wedge-shaped insulating bricks. The number of straight and wedge-shaped insulating bricks used in combination varies depending on the ring diameter.

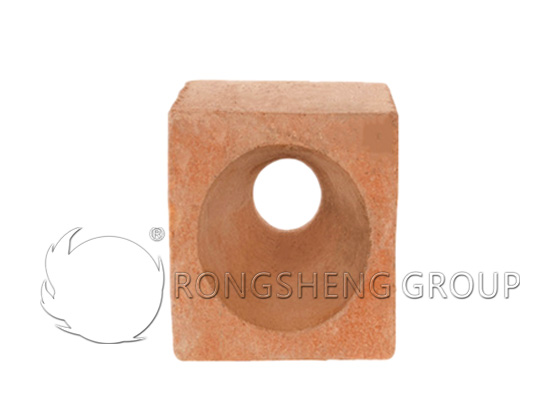

What are the Characteristics of High-Alumina Blasting Lance Bricks?

High-alumina blasting lance bricks, also known as koe bricks, are a type of high-alumina refractory brick. High-alumina refractory bricks are aluminosilicate refractory materials with an alumina content of 48%+.

The production process of high-alumina koe bricks involves crushing, mixing, molding, drying, firing, inspection, and packaging. They exhibit good compressive stress resistance at low temperatures, but this decreases slightly at high temperatures, therefore, they should be stacked at a depth of less than 1 meter in the kiln. The production process of high-alumina koe bricks is similar to that of multi-clinker clay bricks, but the difference lies in the higher proportion of clinker in the batch, reaching 90%–99%. The clinker needs to be graded, screened, and iron-removed before crushing. The firing temperature is relatively high; for example, high-alumina refractory bricks of grades I and II are typically fired at 1500–1600℃ in a tunnel kiln.

High-alumina blasting lance bricks possess high refractoriness, good resistance to acid and alkali corrosion, high high-temperature strength, and good thermal shock stability. They also exhibit excellent high-temperature mechanical properties and resistance to chemical corrosion. High-alumina lance bricks exhibit high softening temperature under load, good resistance to high-temperature creep, and excellent thermal shock resistance.

High-alumina lance bricks are primarily used for lining blast furnaces, hot blast stoves, electric furnace roofs, blast furnaces, reverberatory furnaces, and rotary kilns. In addition, high-alumina bricks are widely used as checker bricks in open-hearth furnaces and as plugs in casting systems.

The standard dimensions of high-alumina lance bricks are 300*300*200mm. High alumina bricks specification. The front diameter is 230mm, the rear diameter is 140mm, and the weight is 3.5kg (actual weight may vary).